HYBRIT has built a pilot hydrogen storage plant in Svartöberget, in Luleå, Sweden. The tests in the pilot storage will take place in 2022-2024. The pilot hydrogen storage plant connected to the pilot plant for direct reduction by a pipeline and all hydrogen to be used in the storage is produced in the direct reduction pilotplant. In the plant at Svartöberget, hydrogen storage will be tested in the storage facility using known technology known as LRC (Lined Rock Cavern). This means the gas is stored underground in a rock cavern whose walls are lined with a selected material as a sealing layer.

In the HYBRIT process, the fossil-free hydrogen is central. It is produced by electrolysis of water and is used in the direct reduction shaft to remove the oxygen from the iron ore pellets. The electrolysis is done using fossil-free electricity. The hydrogen that will be used in the process is produced next to the direct reduction plant and can be used directly or stored.

Storing hydrogen provides an opportunity to stabilize the energy system by producing hydrogen when there is plenty of electricity, for example when it is windy, and using the stored hydrogen when the electrical system is under strain. To secure the availability of fossil-free hydrogen, it is important that it can be stored under safe and efficient conditions. The plant will be built according to the high standards that apply and its safety will be scrupulously reviewed to ensure compliance with the demands from society and authorities.

The technology for storing gas in a lined rock cavern (LRC) is well proven and has been used in southern Sweden for about 20 years for storing natural gas. Now the technology is taking a step forward by thea development for storage of hydrogen gas, and the storage facility will also be used more dynamically, being filled and emptied at pace with the hydrogen production.

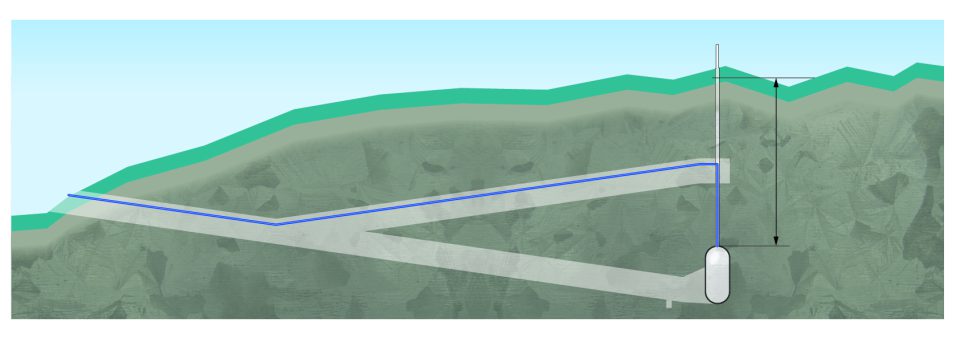

The rock cavern in Svartöberget where the gas is stored is about 30 metres below ground level and 100 metres from the entrance. The pilot plant has a size of 100 cubic metres. At a later stage, a full-scale hydrogen gas storage facility measuring 100,000 to 120,000 cubic metres may be required, in which case it will be able to store up to 100 GWh of electricity converted to hydrogen gas, which is sufficient to supply a full-sized sponge iron factory for three to four days.

Mikael Nordlander, Development Manager for Vattenfall’s industrial partnerships, on storing hydrogen in lined rock caverns and why HYBRIT is aiming to store hydrogen.

Join us for a virtual tour of our hydrogen storage.